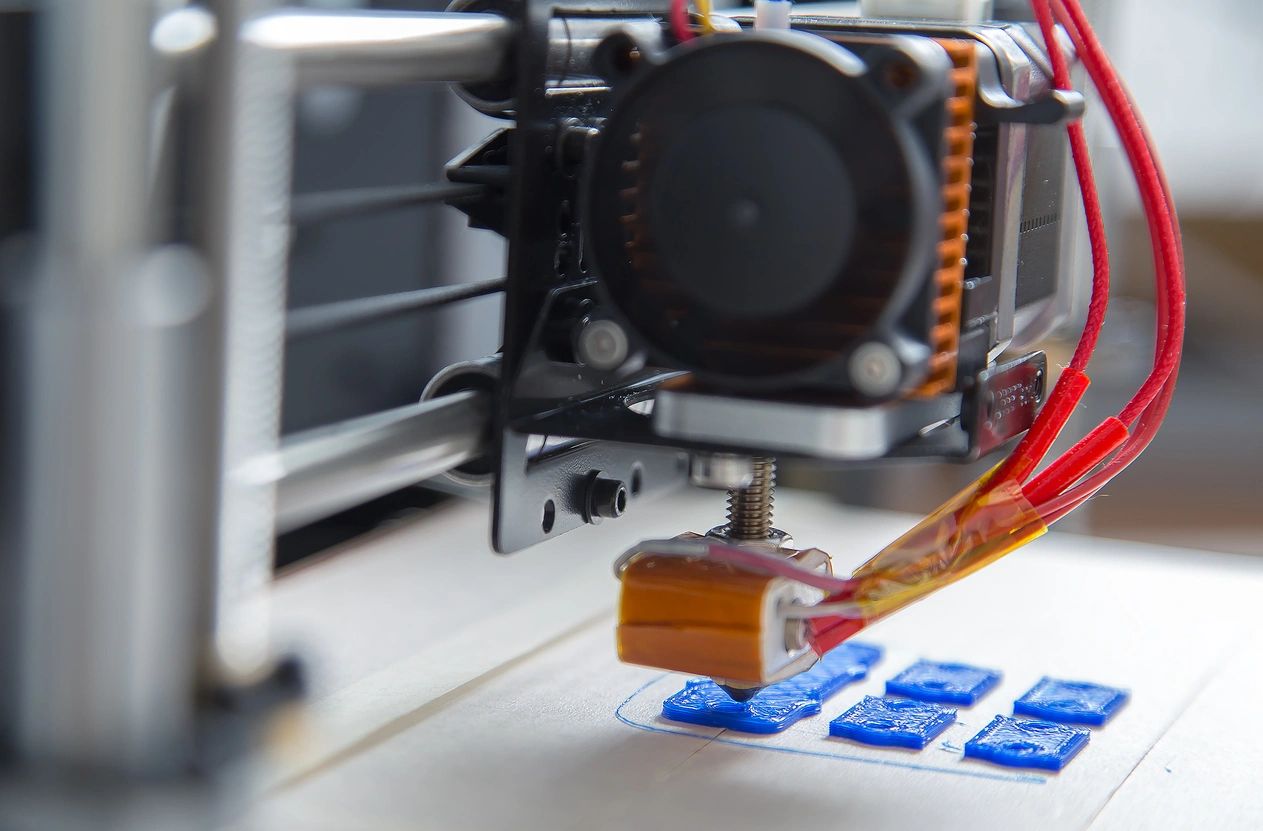

3D printing, also known as additive manufacturing, has rapidly emerged as a groundbreaking technology in the manufacturing sector, fundamentally altering how products are designed, prototyped, and produced. This innovation, once confined to the realm of experimental labs, is now a mainstream manufacturing method, offering unprecedented flexibility, efficiency, and cost-effectiveness.

Traditional manufacturing methods, often referred to as subtractive manufacturing, involve cutting, drilling, or milling material away from a solid block to create a final product. This approach, while effective, typically generates a significant amount of waste and requires complex machinery. In contrast, 3D printing builds objects layer by layer, using only the material necessary to create the final product. This not only minimizes waste but also allows for intricate designs that would be difficult or impossible to achieve with conventional methods.

The ability to produce complex geometries is one of the key advantages of 3D printing. Engineers and designers are no longer constrained by the limitations of traditional manufacturing techniques. Instead, they can create parts with internal structures, intricate details, and customized features, all without the need for additional tooling or assembly. This capability has opened up new possibilities in industries ranging from aerospace and automotive to healthcare and consumer goods.

One of the most significant impacts of 3D printing on modern manufacturing is the acceleration of the design-to-production cycle. In the past, developing a new product often required months of prototyping and testing, with each iteration involving time-consuming and costly processes. 3D printing has dramatically shortened this timeline by allowing for rapid prototyping. Designers can now create, test, and refine prototypes in a matter of days, rather than weeks or months. This agility is particularly valuable in industries where time-to-market is critical. Companies can respond more quickly to market demands, bring products to market faster, and iterate on designs with greater ease. In addition, 3D printing enables on-demand production, reducing the need for large inventories and allowing for more efficient use of resources.

Another transformative aspect of 3D printing is its potential for mass customization. Traditional manufacturing is typically geared toward mass production, where economies of scale are achieved by producing large quantities of identical items. However, 3D printing makes it possible to customize each product without significant cost increases. This capability is particularly beneficial in industries like healthcare, where personalized medical devices, prosthetics, and implants can be tailored to the specific needs of individual patients. The ability to produce customized products on demand also extends to consumer goods, where brands are increasingly offering personalized products, from footwear to jewelry. This trend is reshaping consumer expectations and driving a new wave of innovation in product design.

Despite its many advantages, 3D printing is not without its challenges. The technology is still evolving, and there are limitations in terms of material options, production speed, and part size. Additionally, the quality and consistency of 3D-printed parts can vary, requiring ongoing improvements in process control and standardization. Nevertheless, the future of 3D printing in manufacturing looks promising. As the technology continues to mature, it is expected to become more accessible, affordable, and capable of handling a broader range of materials and applications. With ongoing advancements, 3D printing is poised to further revolutionize manufacturing, offering new opportunities for innovation and reshaping the way products are made.

Comments are closed